How not to get punctured on the moon: engineers invent ultra-durable tires

The return to the moon after half a century and upcoming missions to Mars require not only new rockets and ships, but… rethinking wheels. Because at a distance of hundreds of millions of kilometers,… a flat tire is no longer a small thing, but a potentially fatal problem.

No flat tires: engineers’ challenges

“A puncture is something we can’t afford,” says Florent Menego, CEO of France’s Michelin. His company is developing new types of airless wheels for use in the extreme environments of the moon and Mars.

A new type of airless wheel for use in the extreme environments of the moon and Mars.

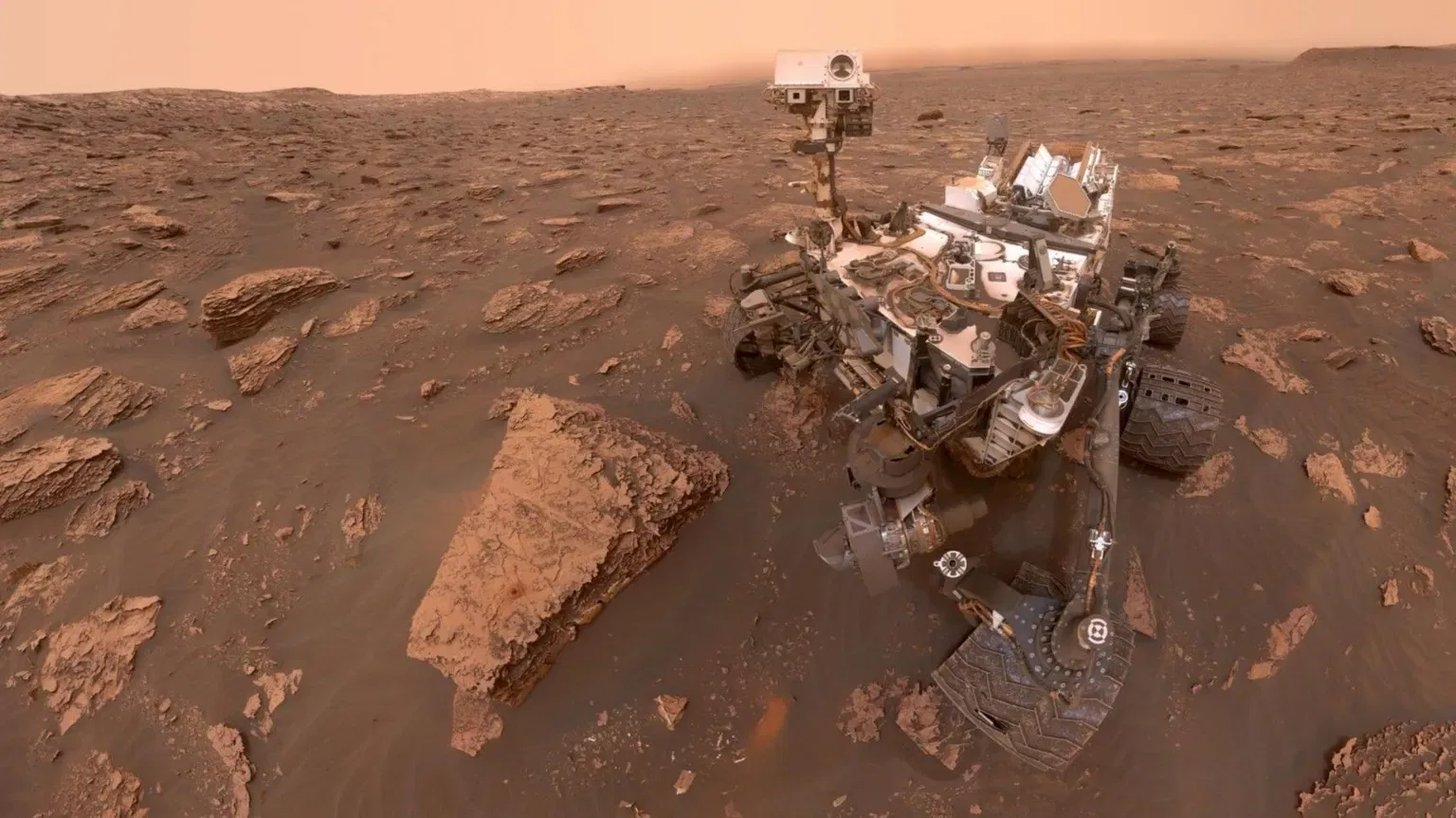

The experience of NASA’s mission with the Mars rover Curiosity showed how aggressive the alien environment is: already a year after landing, the aluminum wheels were covered with cracks and breaks. This was a signal to the engineers: they needed solutions that could withstand not just months, but also decades of use.

Target: 10,000 kilometers across the moon

The US Artemis program, which plans to return astronauts to the Moon starting with Artemis V in 2030, is expected to use a new lunar rover. It will have to travel up to 10,000 kilometers in 10 years -that’s 250 times what the crews of «Apollo» have traveled.

Problems: frost, dust and overload

- Temperatures at the Moon’s poles fall below -230°C, approaching absolute zero – under such conditions materials stop deforming, and thus lose the ability to «work» like a wheel.

- The surface is strewn with sharp rocks and dust, and new lunar rovers will be heavier and more complex than previous ones, with life-support modules and scientific equipment.

- On Mars, things are even more complicated – there gravity is almost twice as high as on the Moon.

“If the wheel can’t return to its original shape, efficiency is lost, power consumption increases, and the mission is jeopardized,” explains Dr. Santo Padula of NASA.

What materials are being used?”

- Michelin relies on high-strength plastics that can withstand deformation and recover without wear.

- Bridgestone is taking a biomimetic approach – inspired by the soft cushions on camels’ feet that don’t fall through sand. The prototype tire is flexible metal spokes and a felt covering.

- ESA and The Smart Tire Company are testing a new generation of materials: nitinol, an alloy of nickel and titanium that has “shape memory.” It works like metal, but behaves like rubber: it bends and springs back without losing structure.

“It’s one of the most amazing properties you’ll ever see,” says Smart Tire Company Earl Patrick Cole.

Where are space tires being tested?”

- Michelin is running prototypes on volcanic ash near Clermont-Ferrand, where the surface resembles that of the moon.

- Bridgestone uses the sand dunes of Tottori in Japan.

- NASA is gathering proposals from different consortia, including Michelin, Bridgestone and Venturi Astrolab, for a test at the John Glenn Center in May.

Ideas for the Earth

Engineers are already thinking about commercial applications for the technology. In 2024 Smart Tire Company will release bicycle tires made of nitinol -they don’t puncture, don’t wear out, and cost about $150. Next up are motorcycle tires for off-road use.

“I want to tell my kids one day: look at the moon – the tires your father made are riding there.”

The How not to get punctured on the moon: engineers invent heavy-duty tires was first published at ITZine.ru.