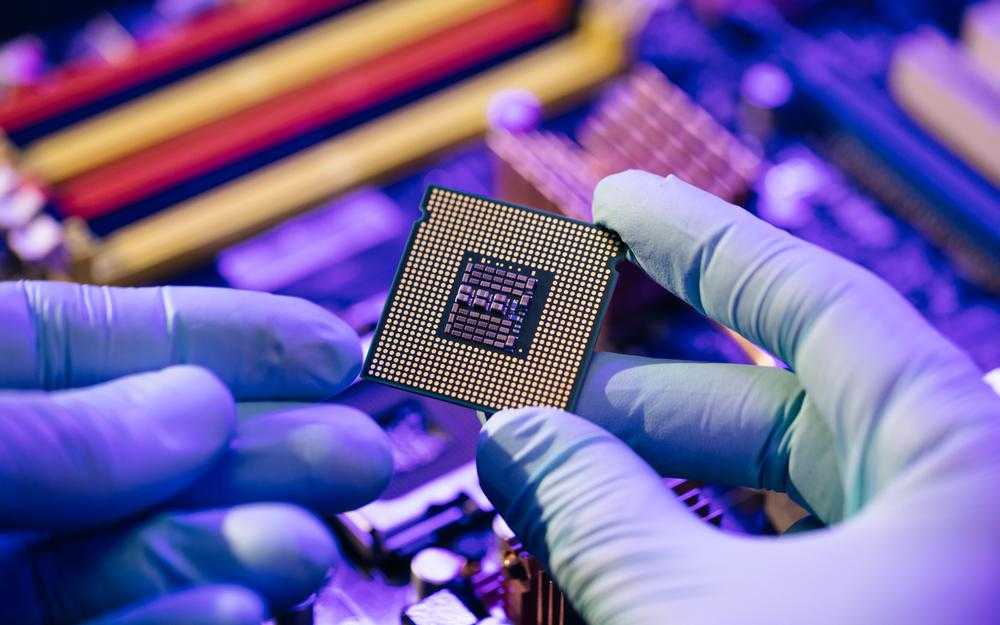

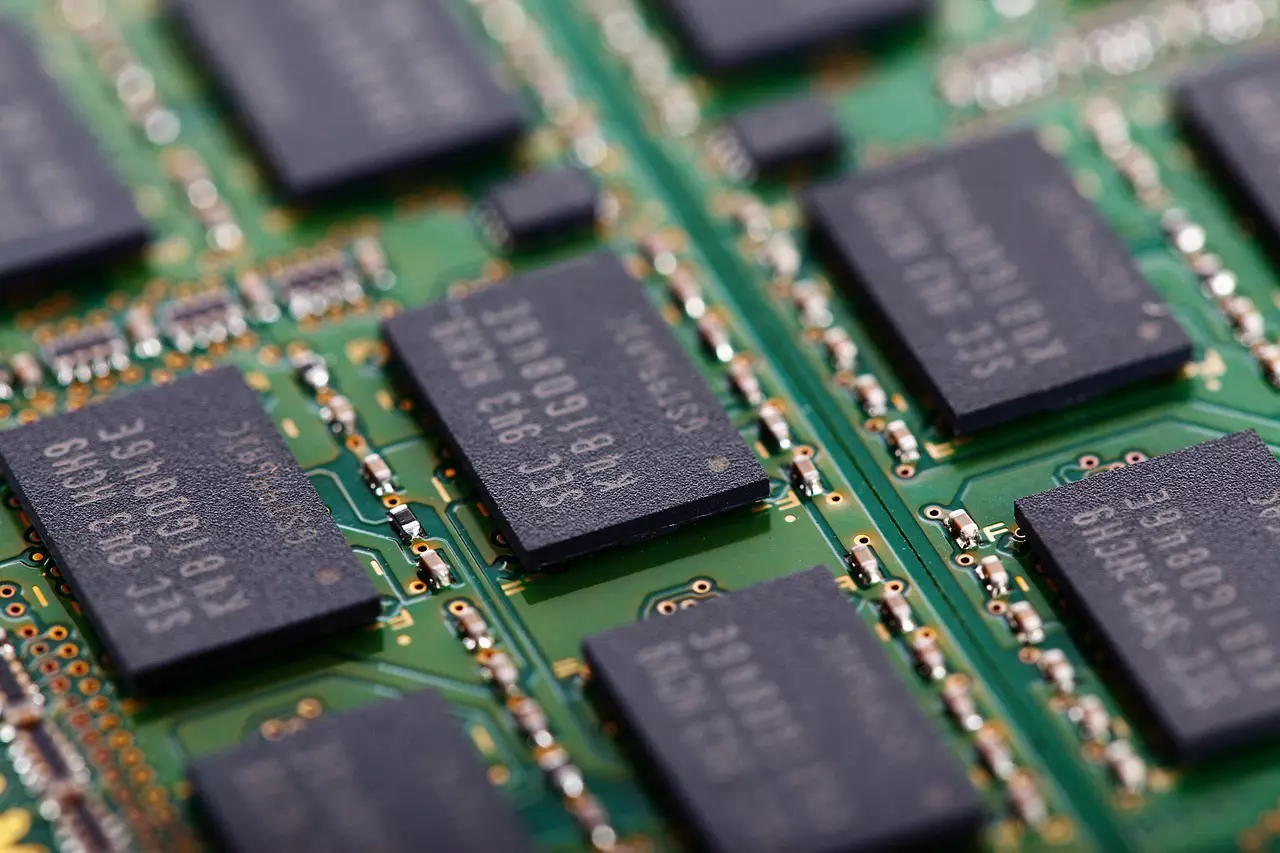

Challenges for chipmaking: Power consumption, emissions, and the pursuit of environmental efficiency

Scientists at Harvard have found that the bulk of emissions associated with electronic devices are related to the energy consumed in their use as well as the production of chips. In 2020, there were set record carbon emissions at chip factories, which consume several tens of thousands of cubic meters of water each day. Each cubic meter of water during transportation and purification generates more than 10 kg of carbon emissions.

As the demand for chips increases, manufacturers are increasing their energy consumption, causing their carbon footprint to grow. The biggest challenges in this area are in Asia-Pacific, a major hub for the global semiconductor industry. This region generated $330 billion in revenue in 2022, more than half of the global total. Leaders in chip production are Taiwan and South Korea. Both countries aim to reach zero emissions by 2050, but for now that remains just a plan. In 2020, Taiwanese TSMC’s emissions, including both their own operations and purchased energy, were about 10 million tons, roughly equal to those of the capital Taipei. In 2021, Samsung of South Korea showed emissions of 15.6 million tons.

Subsidiaries of these manufacturers that specialize in eco-friendly solutions are playing an important role in implementing plans to reduce emissions. For example, TSMC already gets 9% of its energy from renewable sources.

Hydrogen is an important raw material for microchip production. However, for companies, the challenge is not only to have access to hydrogen, but also to produce it without generating carbon dioxide. In Europe, the company Linde has already solved this problem and organized the supply of hydrogen to the Austrian plant Infineon. However, the production of «pure»hydrogen —is only the first part of the solution, since the transport infrastructure for its delivery is also required. Samsung’s C&T division has excelled in this area, having succeeded in building a complete chain from hydrogen production from ammonia to delivery of the finished product to the domestic market. Another Samsung division is developing environmentally friendly hydrogen propulsion systems for water transport.

Samsung SDI has already become one of the world’s leading energy storage manufacturers, capturing about a tenth of the global market. SK hynix subsidiaries account for another 6 percent of the market. As emission targets are revised by governments, demand for energy storage systems is growing. Analysts believe this market will double to $430 billion by 2030. Energy storage systems are becoming smaller and lighter, and the number of battery cells in them is increasing. Samsung SDI also announced record profits in the first quarter, exceeding $4 billion.

Asian semiconductor manufacturers have to factor in projected demand when planning production capacity. One factor influencing demand today is the growing demand for artificial intelligence systems as well as compliance with new emissions regulations.

Source: Financial Times