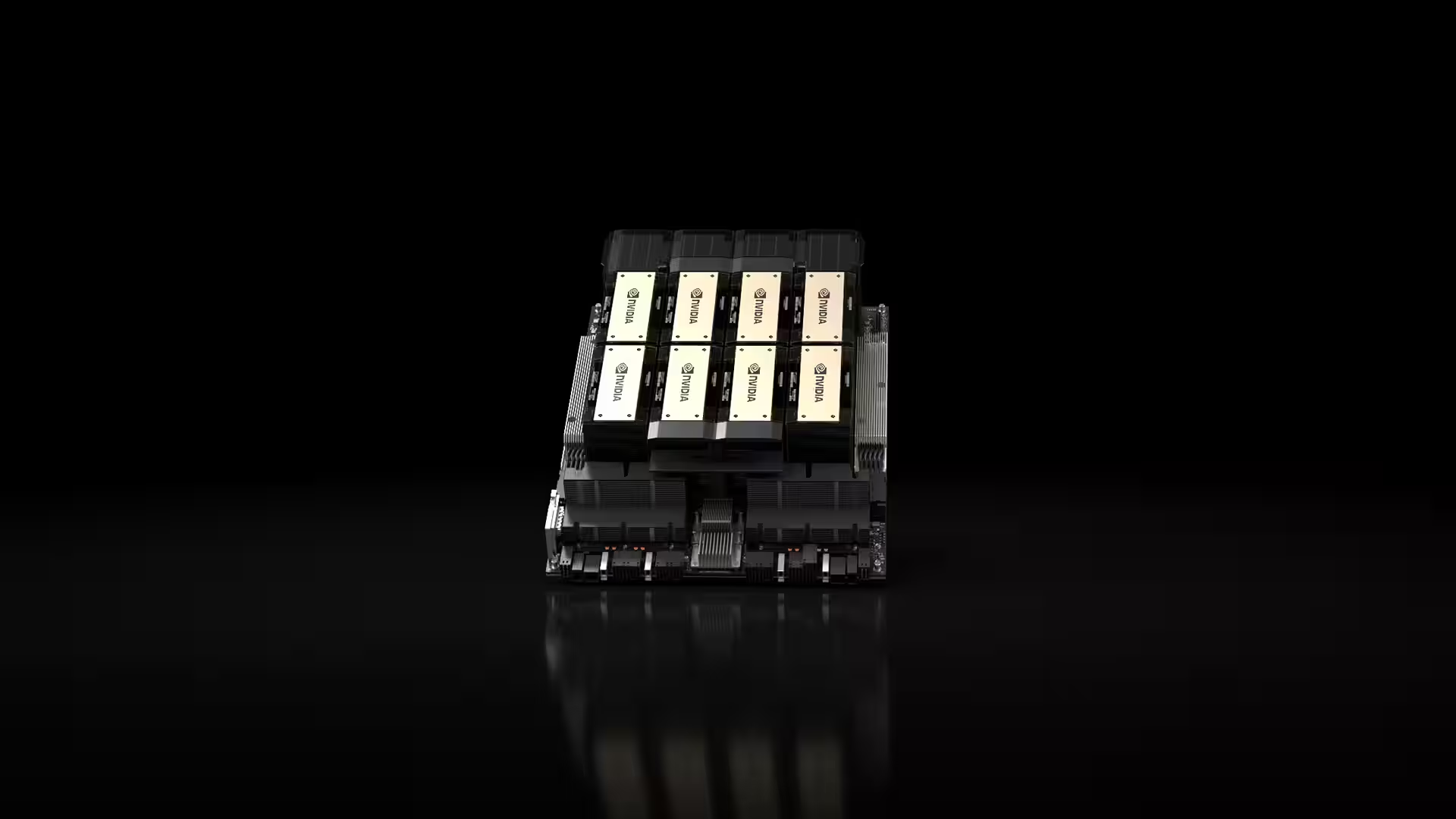

Nvidia, TSMC and other giants are booking chip production in the US

Harsh export restrictions imposed by the US against China continue to redefine the global balance of power in the semiconductor industry. Amid possible new tariffs on chip imports, the world’s largest chip makers – including Nvidia – have begun actively booking TSMC’s Arizona manufacturing facilities to protect themselves from new tax hits.

A scenario in which U.S. assembly becomes more cost-effective than imports seemed impossible just a few years ago. But today, amid trade wars, equipment shortages and government pressure, the biggest tech giants are rethinking their strategies.

Sanctions against Huawei and the subsequent technology gap

The origins of the current changes go back to 2020, when the US imposed severe restrictions on high-tech chip exports to China. Huawei was particularly hard hit, with its HiSilicon subsidiary losing access to state-of-the-art process technology, including 5nm and 3nm nodes. After the release of the flagship Mate 40, the company was forced to release smartphones on Snapdragon chips adapted for 4G.

The solution was to switch to China’s SMIC fab, which began producing Kirin 9000s processors for the Mate 60 lineup using the 7nm process. This allowed Huawei to bring back 5G support without formally breaking sanctions. However, SMIC is still technically limited by its lack of access to EUV lithography equipment, which prevents it from moving to the more advanced 5nm, 3nm, and 2nm process technologies.

At the same time, SMIC is still limited by its lack of access to EUV lithography equipment, which prevents it from moving to the more advanced 5nm, 3nm, and 2nm process technologies.

By the end of 2025, TSMC and Samsung Foundry continue to make steady progress toward mass production of 2nm chips. This leaves the Chinese industry at least three generations behind.

US may impose tariffs on chip imports: industry in panic

Recently, former US President Donald Trump proposed taxing all semiconductors imported into the country. Although it’s still an unofficial initiative, major market players have taken it seriously. According to DigiTimes, customers who previously rejected American manufacturing because of high costs are now actively turning to TSMC’s Arizona fab.

The intention is obvious: to place orders within the U.S. and thereby avoid new duties. But this strategy has its pitfalls – production at TSMC’s U.S. factory is limited, and demand is rapidly outstripping supply.

And in economics, that means one thing: higher prices. Already, production at the 4nm node in Arizona is expected to be noticeably more expensive than in Asia. And that’s not to mention the 2nm process, where a single silicon wafer costs about $30,000 – 50% more than 3nm did a few years ago.

And the economics mean it’s already expected to be noticeably more expensive than 3nm.

Scarcity, high prices and end-user implications

Silicon wafers are the backbone of modern chips: multilayer structures are deposited on them, which are then sliced into individual crystals. It is their cost of production that is now becoming a key pricing factor in the entire chain from design to final device.

Silicon wafers are the foundation of modern chips: they are deposited with multilayer structures that are then sliced into individual crystals.

Apple is rumored to have already abandoned the idea of using it for the A19 and A19 Pro processors in the iPhone 17 due to the high cost of 2nm manufacturing, switching to the more mature and relatively cheaper 3nm node.

Apple has already abandoned the idea of using it for the A19 and A19 Pro processors in the iPhone 17, switching to the more mature and relatively cheap 3nm node.

It’s expected that even without the tariffs officially imposed, retail prices for smartphones in the U.S. will start to rise – simply because the entire supply chain is getting more expensive. Manufacturing inside the U.S. is not only a way around sanctions, but it’s also the price of economic independence that consumers seem to have to pay.