Mercedes-Benz and Factorial: a revolution in electric vehicles with solid-state batteries

Mercedes-Benz has made a breakthrough in electric vehicles with the start of road trials of a new solid-state battery pack in conjunction with Factorial Energy. The technology, developed with engineers from Mercedes AMG High Performance Powertrains (HPP), promises a range of over 1,000 kilometers – 25 percent more than current EQS models. Here’s how it was made possible and what it means for the future of transportation.

The Synergy of Innovation: Mercedes-Benz + Factorial

.

The collaboration between Mercedes-Benz and Factorial Energy started in 2021, but the first fruits of the partnership are only now appearing. In the summer of 2024, Factorial supplied Mercedes with lithium-metal solid-state cells based on the FEST (Factorial Electrolyte System Technology) platform. These are the world’s first samples of this type of battery delivered to the automaker for integration into a series-production platform.

Factorial’s lithium-metal solid-state cells are the first of their kind in the world.

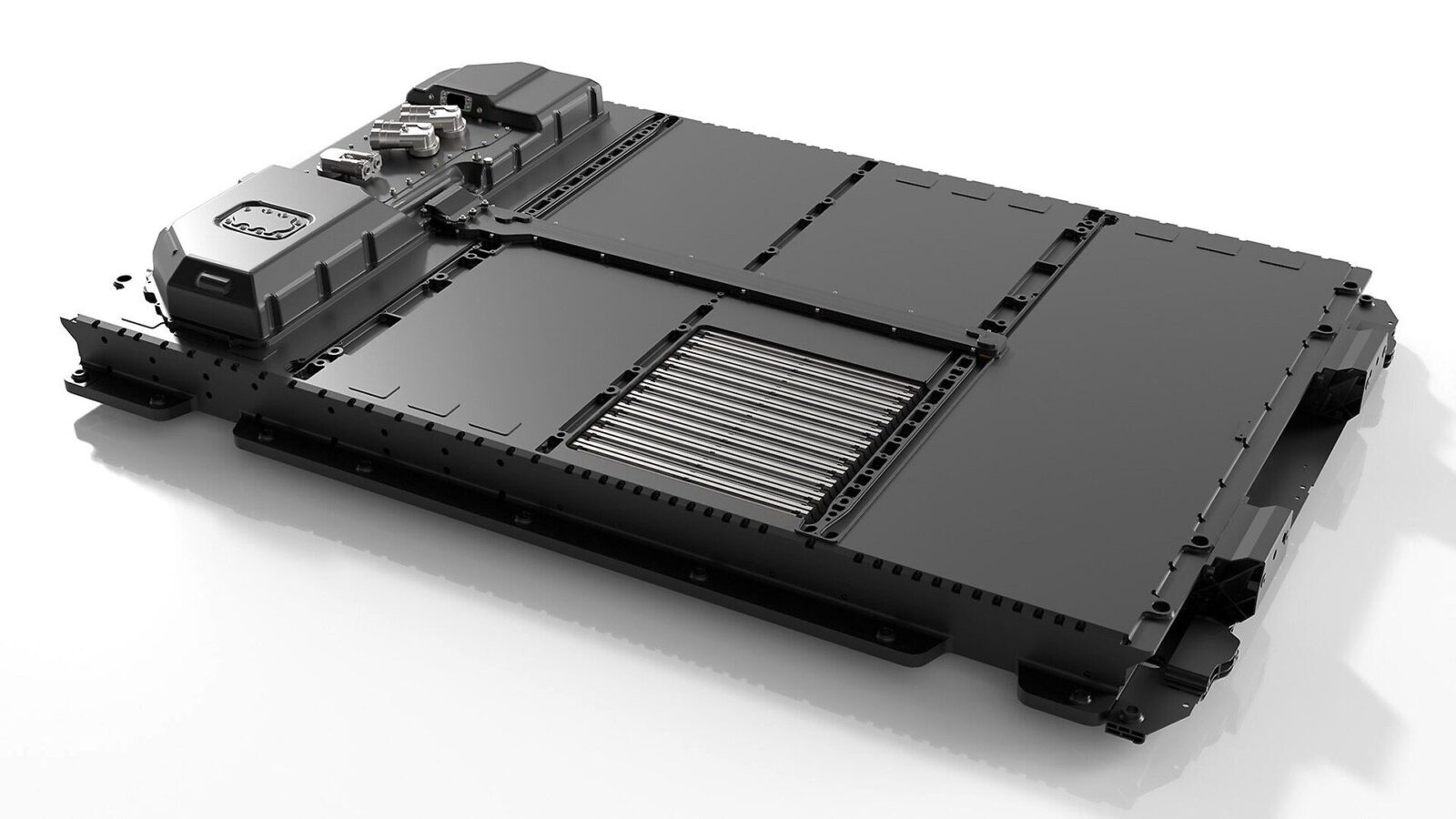

The Mercedes AMG HPP division, known for Formula 1 technology, played a key role in the project. Their experts worked with the Mercedes Battery Competence Center to develop an innovative battery system with the company’s patented floating cells.

An innovative battery system with floating cells was developed by Mercedes AMG HPP.

Solid-state batteries: why is this a breakthrough?”

.

Solid-state batteries replace liquid electrolyte with solid electrolyte, which increases safety and allows the use of lithium-metal anodes. This increases gravimetric energy density to 450Wh/kg (at the cell level), a figure unattainable with traditional lithium-ion batteries.

Solid-state batteries are also a great way to increase energy density.

Benefits of the technology:

- Safety: Solid electrolyte reduces the risk of fire.

- Longevity: Pneumatic actuators compensate for material expansion during charge/discharge, extending life.

- Efficiency: Passive cooling reduces system weight and power consumption.

The prototype installed on the EQS weighs the same as the standard battery, but provides a range of 1000+ km vs. 800 km for the EQS 450+.

Testing: from the lab to the roads

At the end of 2024, the first EQS prototype with a solid-state battery took to the test track in Stuttgart. By February 2025, full-scale road tests began.

At the end of 2024, the first EQS prototype with a solid-state battery began test drives in Stuttgart.

“The integration of solid-state batteries into a car is a historic achievement. It proves that the technology is ready for the real world, not just the labs,” said Siyu Huang, CEO of Factorial.

“It’s a historic achievement.

Markus Schäfer, chief technology officer of Mercedes-Benz Group, added that the tests will provide key data for series production.

Why is this important to market?

Solid-state batteries solve the main problems of electric cars: limited range and long charging times. Mercedes-Benz plans to continue testing to optimize the technology for the mass market. The project’s success could accelerate automakers’ transition to a new battery standard, making electric vehicles more affordable and practical.

Access of the project could accelerate the automaker’s transition to a new battery standard, making electric vehicles more affordable and practical.

Material Mercedes-Benz and Factorial: Revolutionizing electric cars with solid-state battery was first published on ITZine.ru.