CES 2026: MetalPrinting Gauss MT90 makes metal printing safe in the office

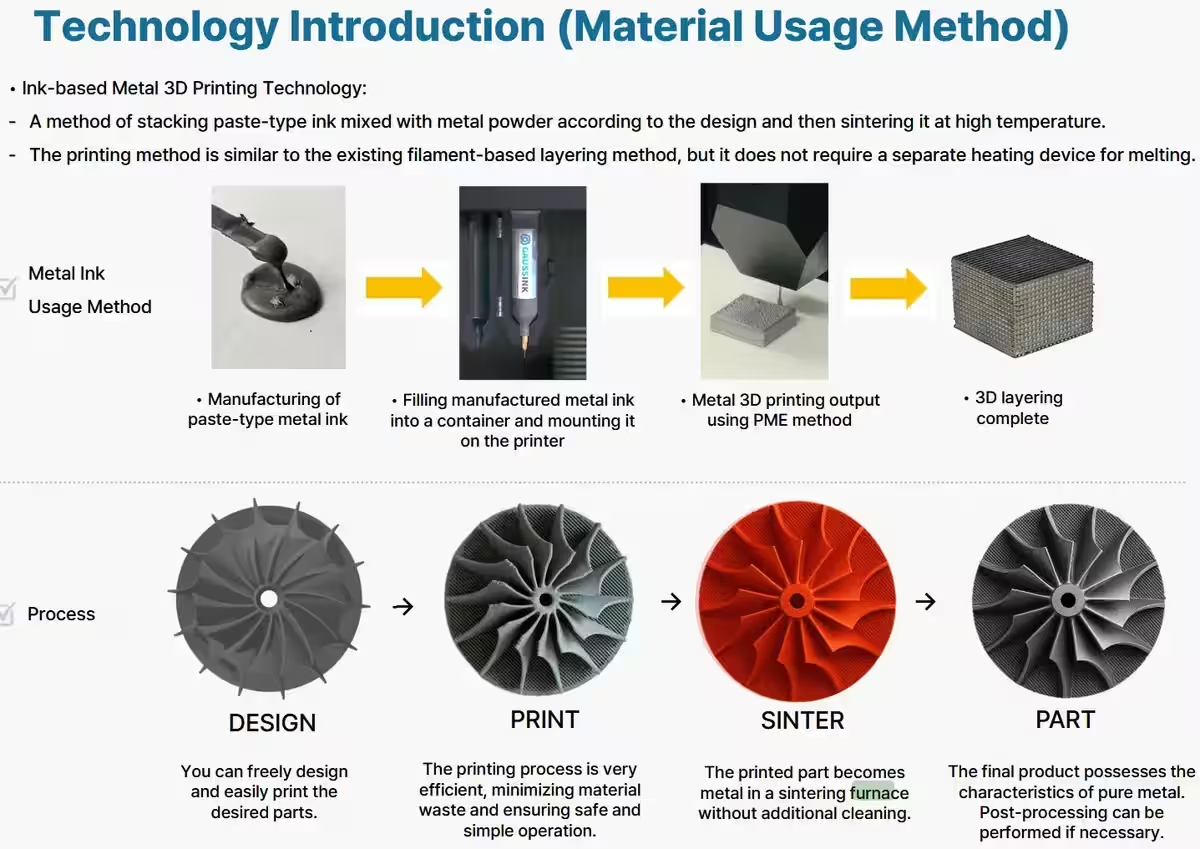

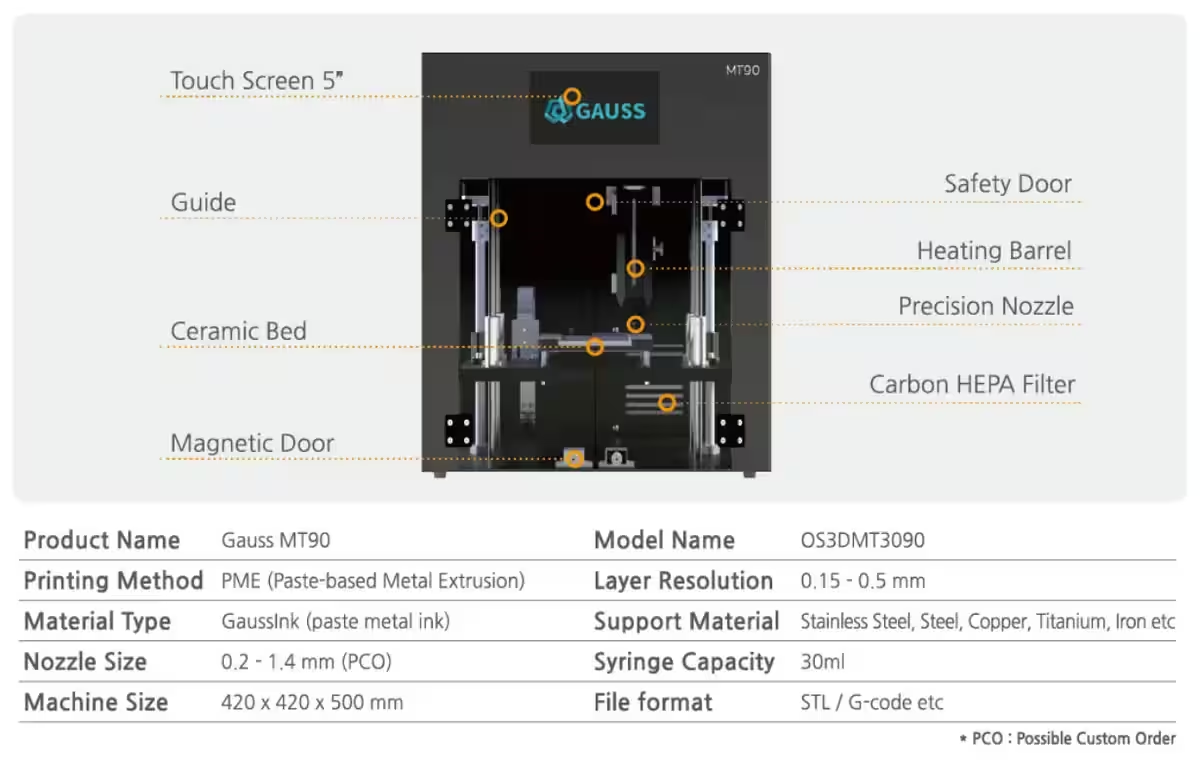

MetalPrinting unveiled the Gauss MT90 desktop 3D printer at CES 2026, designed for metal printing in office environments. The device operates at room temperature, uses no metal powders and is based on PME metal paste extrusion technology, which significantly reduces risks and operational requirements.

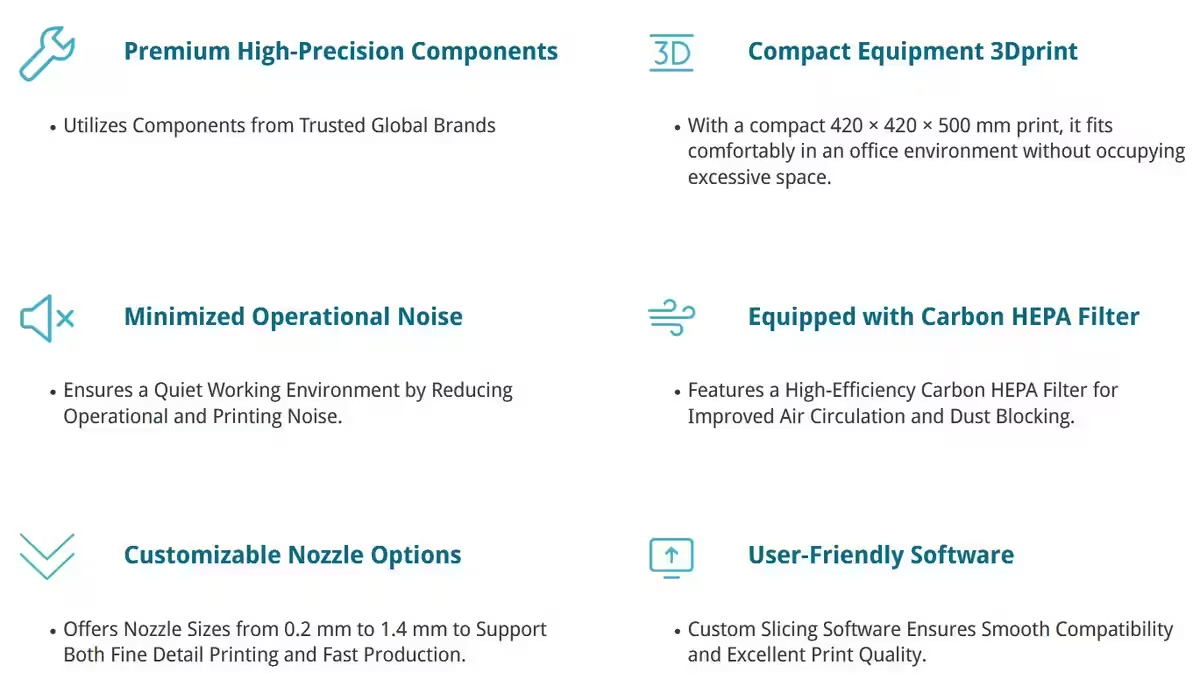

Gauss MT90 is positioned as a compact and enclosed system designed for workspaces without industrial infrastructure. The company says the new printer should make metal 3D printing accessible to a wider range of users, including engineering departments, laboratories, and small companies.

According to the company, the new printer is designed to make metal 3D printing accessible to a wider range of users, including engineering departments, laboratories, and small companies.

What makes the Gauss MT90 different from classic metal printing

Till now, metal 3D printing has largely remained the domain of large enterprises. These systems typically utilize high temperatures and metal powders due to increased safety requirements, risks of fire and explosions, and high equipment and maintenance costs.

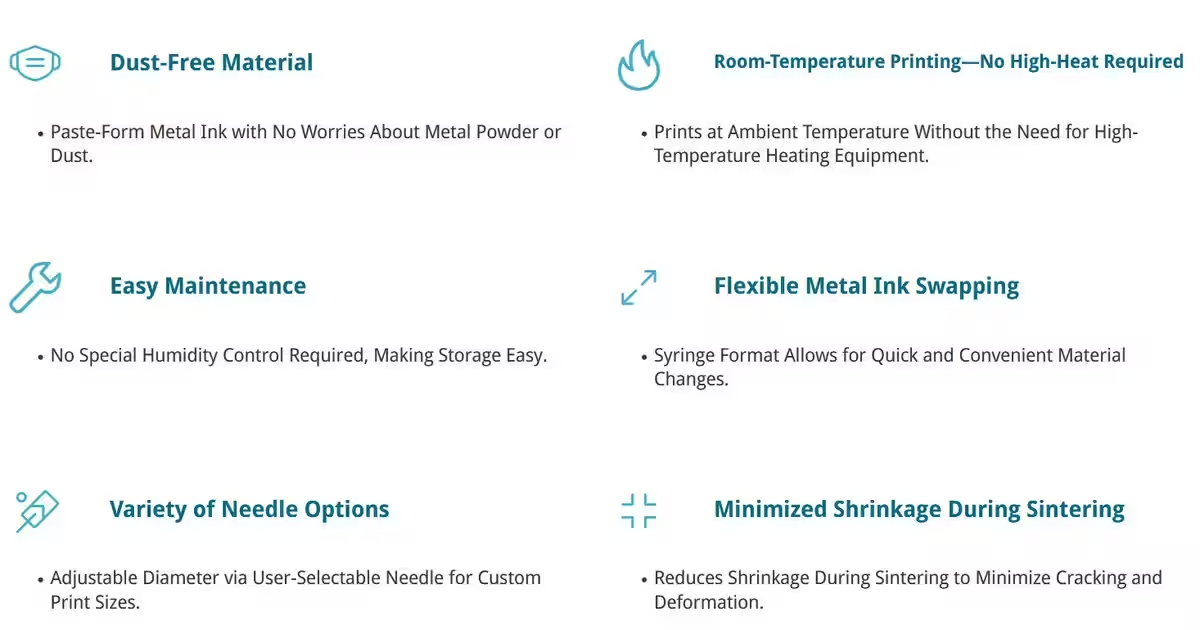

Gauss MT90 fundamentally changes this approach. Instead of powders, it uses a paste-like material that is extruded at room temperature. This reduces the size of the equipment and eliminates the complex protective measures typical of traditional metal printing systems.

GaussInk Paste Extrusion and Materials

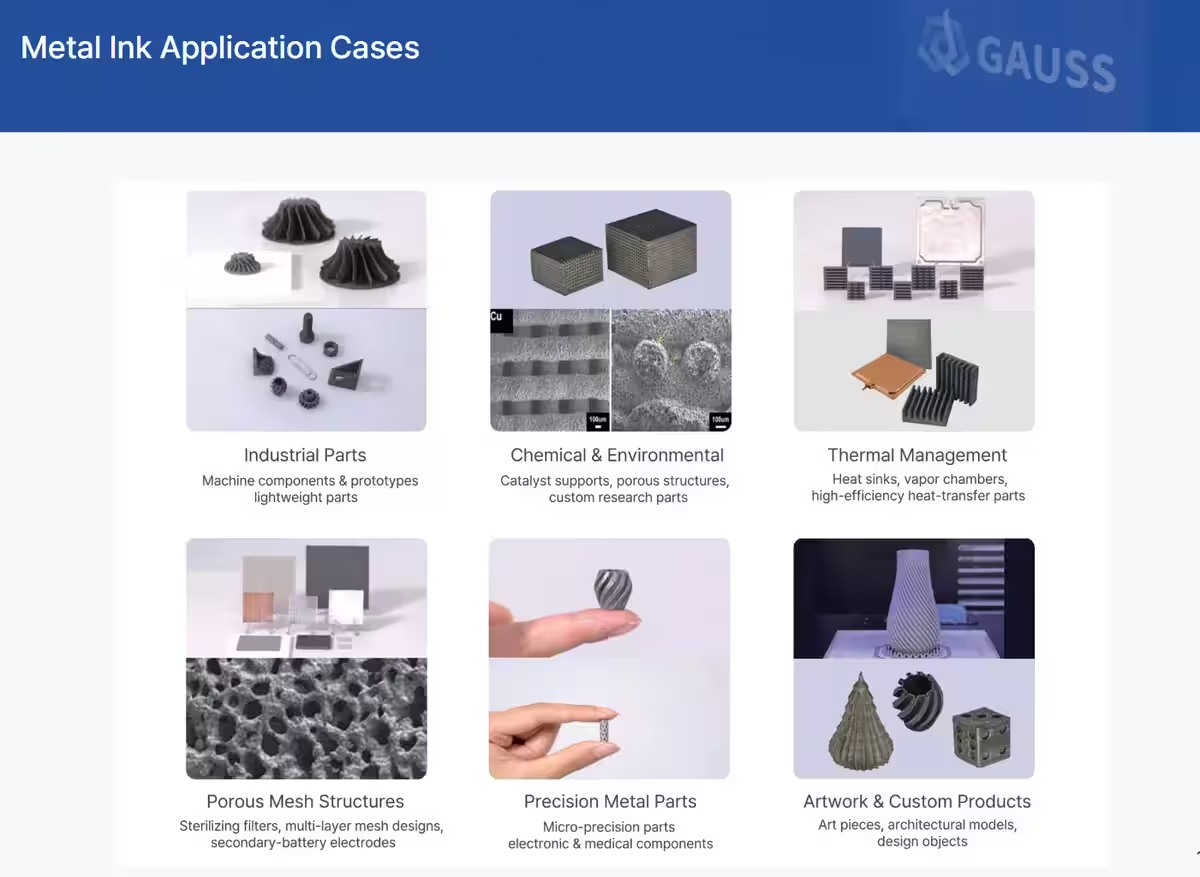

The printer is based on paste-based metal extrusion technology. MetalPrinting has prepared a line of GaussInk replacement cartridges containing paste-based metal inks. Stainless steel, copper, titanium, nickel, iron and tungsten-based materials are standard, but the company says customized and alloyed formulations are available upon request.

From a user’s perspective, using the Gauss MT90 is like using a conventional desktop 3D printer. The cartridges are as easy to install as polymer printing consumables, and the process requires no special conditions or protective suits.

At the same time, the Gauss MT90 is easy to install and does not require special conditions or protective suits.

Design, operation and safety

The Gauss MT90 is designed in a closed desktop format and looks little different from other office 3D printers. The noise level is claimed to be around 40dB, making it suitable for constant work near people.

At the same time, the MT90 has a noise level of around 40dB, making it suitable for constant work near people.

The printer features a built-in HEPA filter that minimizes potential emissions into the surrounding area. It is controlled and monitored via a 7-inch touchscreen display, while an integrated AI-enabled camera monitors the printing process and helps detect problems at an early stage.

The printer has a built-in HEPA filter that minimizes emissions in the environment.

Post-processing and sintering stage

It is important to keep in mind that parts printed on the Gauss MT90 are not fully finished products immediately after printing. The resulting workpieces must be heat-treated in a sintering furnace, where the metal paste particles are finally bonded into a solid part.

The details of the sintering process, as well as the equipment requirements for this step, are limited. Nevertheless, the fact that the high-temperature processing is moved outside the printer keeps the core system safe and compact.

Context and Recognition at CES 2026

MetalPrinting emphasizes that risk mitigation is particularly important against the backdrop of previous examples of metal 3D printing, including experimental setups using extreme temperatures and potentially hazardous materials. In this context, the Gauss MT90 looks to be a more versatile and safer solution.

The printer was recognized with a CES 2026 Innovation Award. The company suggests that information about the launch date and price should be specified directly, indicating that the focus is more on the professional and corporate market than on the mass consumer.