Aysors and K2Tech signed an agreement on strategic technological partnership

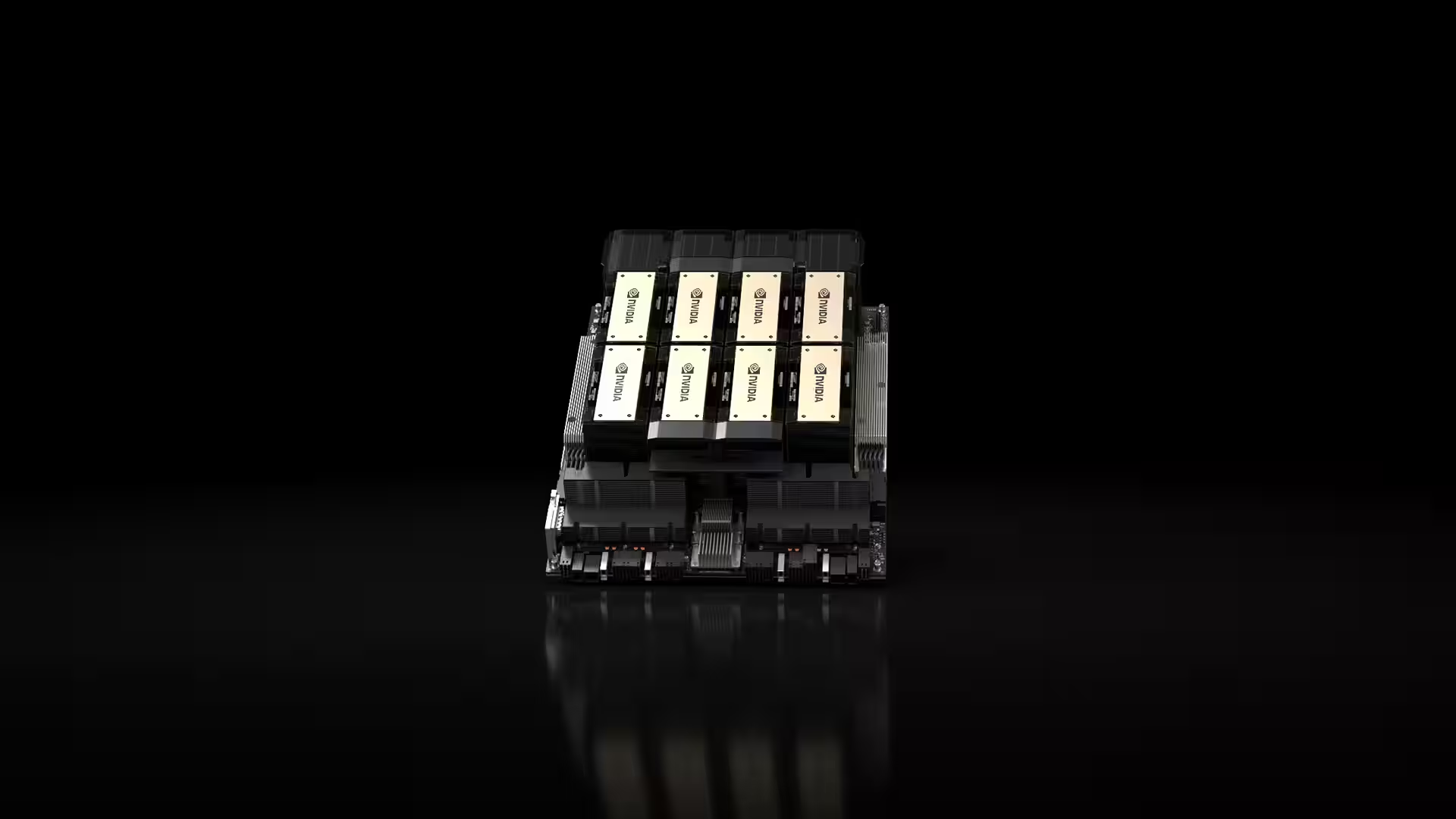

The companies Aisors and K2Tech signed a memorandum of strategic partnership on the margins of the II All-Russian Forum “Industrial Automation: Transition to Open ACS” held in Nizhny Novgorod. The forum is held within the framework of the Industry Code program of the Russian Ministry of Industry and Trade with the support of the Working Group on Open ACS. The partnership is aimed at developing cooperation between the companies in the field of promotion and implementation of Aysors’ own development – Virtual Controller (included in the Register of domestic software under #28867 dated July 28, 2025). K2Tech will use the solution in its own projects and act as an integrator in the implementation of Aysors software and hardware complexes. The development of Aysors is focused on international standards of open architecture, including Open Process Automation Standard (OPAS), and the principles of the domestic initiative to create Open Process Automation System. Key features of the solution include vendor independence, universal architecture and compliance with industry requirements. The cooperation between Aysors and K2Tech will accelerate the digital transformation of Russian enterprises and the implementation of domestic solutions for industrial automation (APCS) and building management (BMS). “A key area of development is the convergence of ACS products with modern IT solutions to create a single integrated automation platform. In this strategy, we rely on the competencies of K2Tech, one of the IT market leaders. The partnership will allow us to combine expertise, increase the efficiency of solutions and reduce dependence on foreign vendors,” – said Aysors Valentin Mishin, Development Director. Deputy CEO of K2Tech Igor Zeldets emphasized that more than half of CIOs surveyed by the company named import substitution as a priority. Using the Aysors Virtual Controller in projects will help “move toward technological independence.” Seldetz said the controller provides flexibility, scalability and independence from specific equipment, reduces implementation time and operating costs, and improves resiliency and cybersecurity of process control. The development was carried out by a team of 40 engineers and programmers from Aysors, and the investment amounted to RUB 300 million.An intelligent well cluster management system has already been implemented on the basis of the technology in Western Siberia. It has made it possible to abandon some physical equipment, unify well and rig management in a single virtual environment and reduce capital expenditures by 15 percent compared to traditional solutions. In addition, a pilot project of Automated Building Management System (ABMS) has been implemented in the Aysors and LIIS engineering center in St. Petersburg. The unified dispatching center reduced energy and operating costs by 10%. By the beginning of 2026, it is planned to connect 11 buildings with a total area of 23,700 m² to the system.

Purposes of the agreement

Joint tasks and directions

K2Tech’s contribution and practical results

Practical Application of the Virtual Controller